It is not what we do

It is how we do it

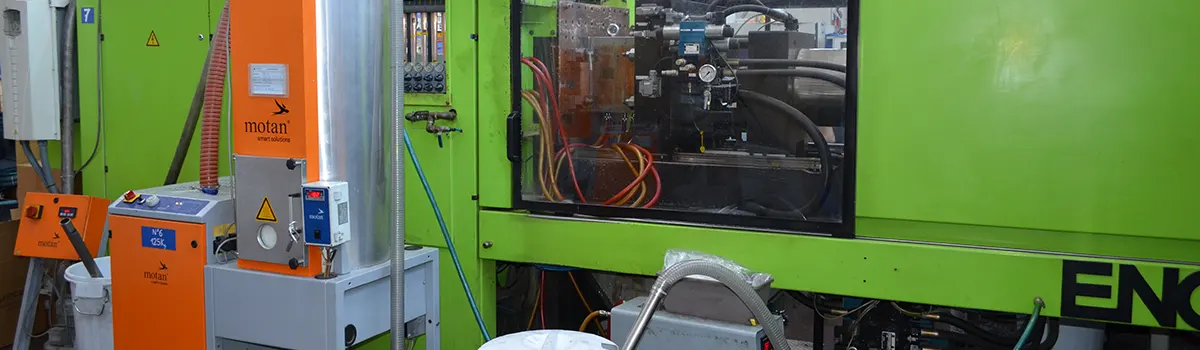

In Plastic 85 we have opted for the 4.0 industry, based on technology, robotization and automation of the processes. We have proven that reliability, productivity and autonomy to work in changing environments is the answer our customers need.

“Our facilities currently have this exceptional infrastructure.”

Automation with machining

Complete automation by 6 axis robot. It includes extraction of piece in injector, Cast cutting, Station for pieces cooling, Machining with milling machine, Artificial vision, fitting with automatic tool change.

Cast cutting with different blades

Automatic station with 6 axis robot for cutting cast with different angles. By type of piece, it is required to have 2 types of cutting blades. Left of piece on conveyor belt.

Shaped and fitted

Complete and very complex automation, where we extract the piece from the injector, eliminate the casting and then shape the pieces in hot to achieve the maximum flatness. Once it is cold, it is fitted with automatic claw change.

Casting cut and Item separation

Station of casting cut (4 cuts in different degrees) with 180º of the blade and its subsequent separation of the two different product models in their respective boxes.